Thermoforming, Simplified

Vacuum and pressure forming are the bread and butter of thermoplastic fabrication, and KYDEX® performs exceptionally in both. With a forming range of 160–205°C and low shrinkage, the material maintains wall thickness and detail across complex geometries.

Vacuum forming works well for simple shapes and short runs. Pressure forming enables fine details, sharper corners, and high-fidelity surface finishes; ideal for consumer-facing applications where texture and edge quality matter.

In both cases, KYDEX® offers a tighter draw ratio and minimal post-trim distortion, giving engineers a high degree of control.

Membrane Pressing, Lamination, and Miter Folding

Where laminates would fail or delaminate, KYDEX® thrives. Its compatibility with membrane pressing makes it a popular choice for contoured cabinetry, curved kiosk panels, and ergonomic retail fixtures.

When edge presentation matters, miter folding is a game-changer. KYDEX® can be V-routed and heat-folded into sharp corners without cracking—no need for edge banding or trim caps. It also adheres cleanly to MDF and phenolic cores using hot- or cold-press lamination, supporting modular builds without sacrificing surface integrity.

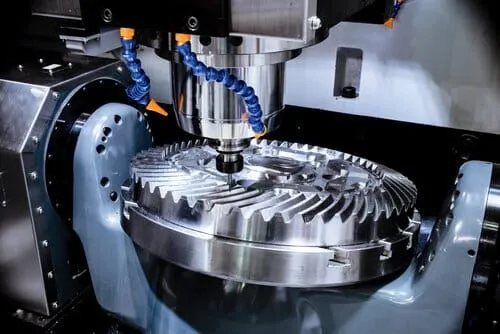

Clean Machining, Sharp Results

CNC machining KYDEX® is almost too easy. Unlike glass-filled polymers or fiber laminates, KYDEX® cuts cleanly with standard woodworking tools. No delamination. No chipping. No hidden voids.

It supports tight tolerances and crisp finishes, making it ideal for enclosures, faceplates, and components that require both form and function. The material is color-through, so even exposed edges retain their finish—no touch-ups required.

Brake Forming and Field Adjustments

KYDEX® can be brake-formed for flanges, edge returns, or adaptive field installations. With a bend radius of 1.5× sheet thickness and a heating range of 105–120°C, it provides flexible post-form options without structural compromise.

This post-form flexibility makes it attractive for retrofit applications, modular builds, and small-batch customization.. especially in sectors like healthcare, retail, and transit infrastructure where environments aren’t always perfectly square.

Assembly Without the Headaches

Whether you’re fastening, welding, or solvent bonding, KYDEX® plays nice with standard joining techniques. Mechanical fasteners (screws, rivets, clips) hold reliably. Chemical bonding with MEK or acrylic adhesives delivers clean joints. And for specialized use, plastic welding is supported on select grades.

For cleanroom or healthcare builds, KYDEX® can be sealed with antimicrobial welds or adhesives, avoiding bacterial harborage or surface degradation over time.

Embedded Branding and Custom Finishes

KYDEX® isn't just tough, it’s customizable. The surface finish is extruded, not applied, meaning it won’t chip, peel, or fade. It supports embossing, hot stamping, digital printing, laser etching, and color matching to Pantone or RAL specs.

For branded environments, this unlocks major potential: display systems, POS kiosks, architectural panels, and more can be fabricated and finished with integrated logos, textures, and color schemes without lamination or overlays.

The Real-World Advantage

When you add up the full picture: compliance, toughness, flexibility, and ease of processing, KYDEX® reveals itself as a material that removes friction from the manufacturing process. It lets engineers and fabricators focus on product function and performance, not patching cosmetic or dimensional flaws.

From deep-draw forming to high-gloss consumer panels, from seamless corners to field-replaceable modules, KYDEX® earns its place not just on the drawing board, but on the production floor.

Need KYDEX® Parts Built Right?

At RapidMade, we help companies design, fabricate, and scale production using the full range of KYDEX® materials and processes, from CNC to thermoforming, branding to assembly.

Start your next project atRapidMade.com

or contact us at info@rapidmade.com

Certified. Scalable. Built to Perform.